WHO WE ARE

Established in 2010 and headquartered in Nanjing, the capital of Jiangsu Province, SpolarPV Technology Co., Ltd stands as a leading force in the solar industry. Our expansive 6,000 m² facility is equipped with state-of-the-art automatic production lines, stringer machines, laminators, and a comprehensive range of manufacturing equipment. Complemented by our imported product testing apparatus, we proudly uphold an annual production capacity of 800MW.

Recognizing the diverse needs of the global market, we have pioneered several innovations in China. We were the first to introduce Building-Integrated Photovoltaic (BIPV) modules and have since expanded our product range to include 182 mm cell modules, 166 mm cell solar modules, bifacial dual glass modules, 158.75 polycrystalline and monocrystalline panel modules, among others.

Our dedication to excellence is evident in our commitment to research, development, and the production of high-efficiency solar modules. We've forged strong partnerships with renowned institutions both locally and internationally, including research institutes in Switzerland and Shanghai Jiaotong University in China. Our credentials are further solidified with certifications like ISO9001, TUV, VDE, RoHS, REACH, IEC 61215, IEC 61730, and CE...

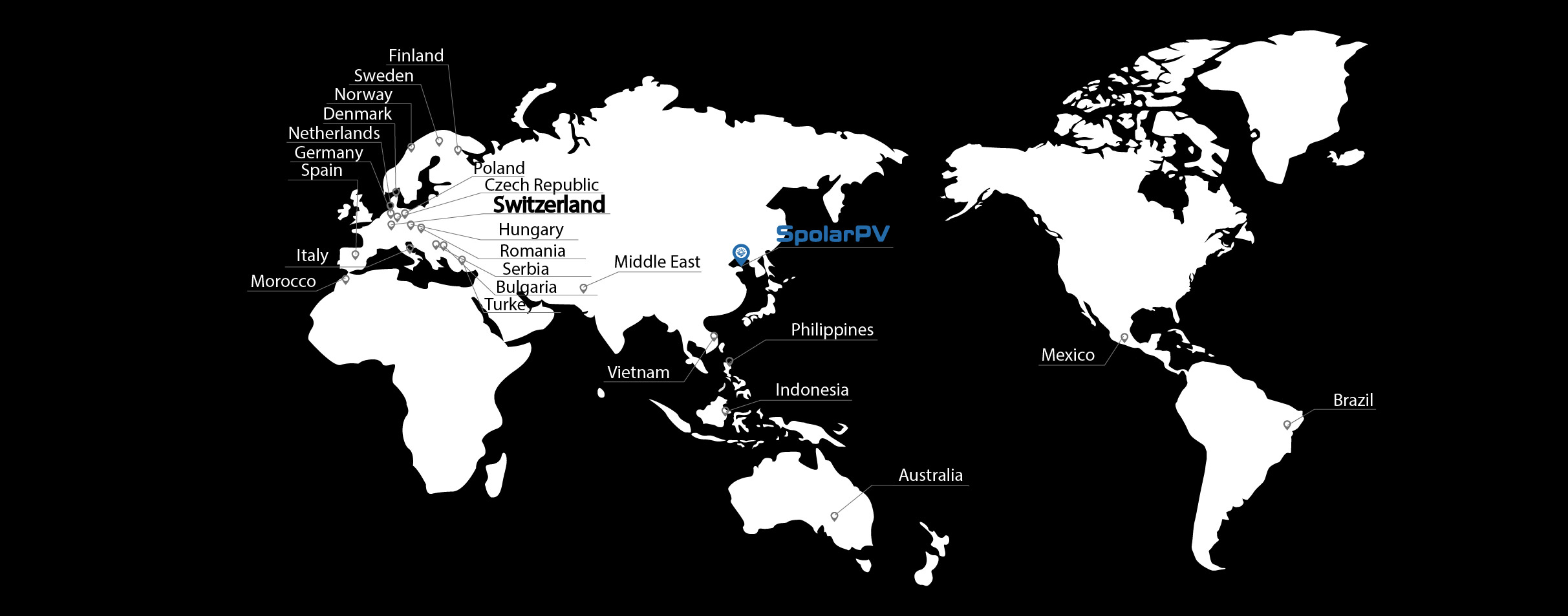

Guided by our belief in delivering only the "Premium and Superior", SpolarPV has consistently prioritized the enhancement of top-tier solar products since its inception. We're not just focused on product quality; we're also dedicated to offering the most cost-effective solutions to our global clientele. Our global footprint includes a technological center and a European market distribution hub in Switzerland. Additionally, we have established branches in countries like Germany, Sweden, Poland, the Netherlands, Spain, Brazil, Vietnam, Afghanistan, and more, covering over 30 countries and regions. We also take pride in offering tailored services to meet the unique needs of our customers.

About SpolarPV Technology Co., Ltd

Vison

Vison

Culture

Culture

Ideal

Ideal

WORLD WIDE SALE

At SpolarPV, our commitment to green energy knows no boundaries. Our solar solutions have illuminated countless homes, businesses, and communities across the globe. While our footprint spans continents, Europe stands as a testament to our most significant market presence. From the bustling cities of Western Europe to the serene landscapes of the East, our solar panels harness the power of the sun, driving sustainability and innovation. As we continue to grow, our dedication remains unwavering: to provide efficient, reliable, and environmentally-friendly solar solutions to every corner of the world.

SpolarPV SALE TEAM

At SpolarPV, our Sale Team stands as the backbone of our success. Comprised of seasoned professionals, each member is deeply rooted in industry knowledge and a passion for solar solutions. Their expertise is not just in understanding the intricacies of the solar market but in translating those insights into tangible benefits for our clients.

Our team's philosophy is simple: the customer comes first. Every interaction is an opportunity to understand our clients' needs better, to offer tailored solutions, and to build lasting relationships. This unwavering commitment to customer-centric service has not only earned us trust but has also positioned SpolarPV as a leader in the solar industry.

As we navigate the ever-evolving landscape of green energy, our Sale Team remains dedicated to excellence, ensuring that every client, big or small, receives the best of what SpolarPV has to offer.

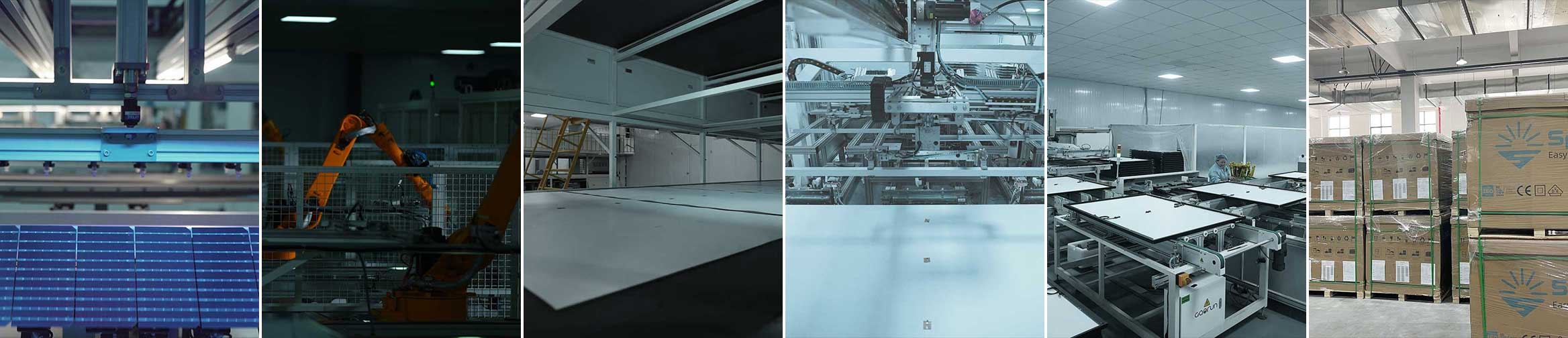

FACTORY

State-of-the-Art Manufacturing

At SpolarPV, our commitment to excellence is deeply embedded in our production processes. Nestled within our factory walls are some of the industry's most advanced equipment, ensuring every solar panel we produce meets the highest standards of quality and efficiency. Our dedication to utilizing cutting-edge technology not only sets us apart but also guarantees the superior performance of our products.

Unparalleled Production Capacity

Our factory is more than just a manufacturing hub; it's where innovation meets scale. With a robust annual production capacity, SpolarPV is poised to meet the growing global demand for solar solutions. Every piece of equipment, every process, and every team member plays a pivotal role in ensuring we deliver not just quantity but unmatched quality to our clients worldwide.